Ingersoll Rand ®

Sales and service center

Brand Mission:Lean on us to help you make life better

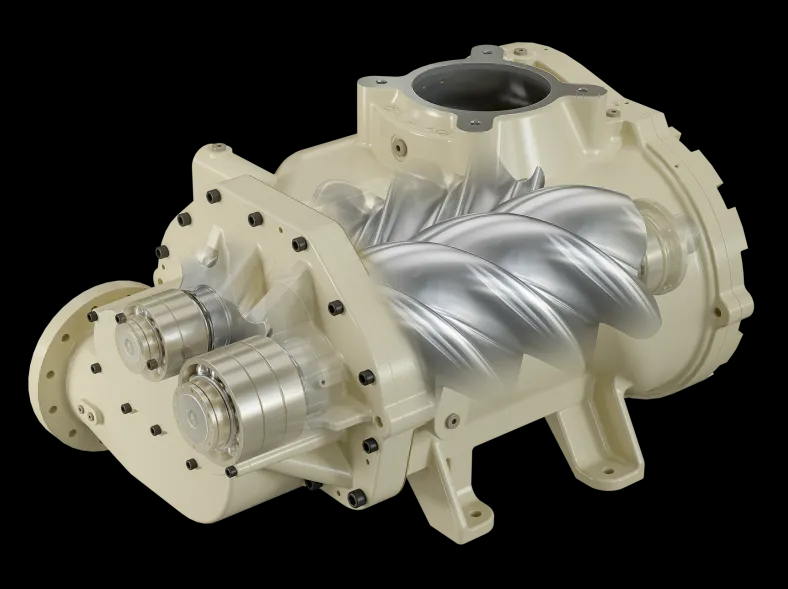

Ingersoll Rand's RM series welcomes a new member: the RM200-250i/n Oil-Flooded Rotary Screw Air Compressors. This new product embodies advanced industrial design and features a highly efficient, energy-saving low-pressure dedicated airend. Its optimized airend, boasting a more advanced rotor profile, significantly boosts efficiency. The design meticulously optimizes bearings, gears, intake and exhaust channels, and the oil injection process for unparalleled efficiency. Through advanced airflow analysis and piping design, components like the air filter, pipes, and connection ports are optimized to maintain low pressure drop, ensuring that the enhanced airend performance directly translates into higher overall unit efficiency. The compressor is equipped with high-performance motors and drive systems, available in both fixed and variable speed options, with generous motor margins to ensure safe operation across the entire regulation range.

Designed Specifically for Low-Pressure Applications

1.Low-Pressure Dedicated Inlet Valve: Offers high sensitivity and quick response to on-site air demand, reducing pressure drop in the intake pipe, saving energy and customer costs.

2.Generous Nano-Coated Air Filter Element: Provides excellent filtration performance while maintaining high airflow.

3.Large-Capacity Cooling System: Meets the cooling demands of high airflow at low pressure, even in harsh operating conditions.

4.Oversized Oil Separator Tank and Element: Ensures more thorough oil-air separation and lower oil consumption.

New Product Features

1. High Energy Efficiency

A new generation airend and drive system, specifically designed for low-pressure applications, deliver superior specific power and flow, reducing energy consumption.

Larger air passages result in lower pressure drop.

Air-cooled units feature dual centrifugal fans for high efficiency, low noise, and large airflow.

2. Reliability

Designed for higher ambient temperatures, enabling adaptation to more severe working conditions.

Large-margin main motor ensures long-term stable operation.

Large-capacity cooling system with stainless steel water-cooled coolers.

Integrated moisture separator reduces the load on downstream treatment and extends equipment life.

Oversized oil separator tank and element ensure more thorough oil-air separation and low oil consumption.

3. Productivity

Same-side pipe connections allow for a smaller footprint.

Intuitive microprocessor control design.

Generous internal space reserved for maintenance, facilitating daily upkeep.

Factory-filled with full synthetic coolant and durable consumables to reduce costs.

4. Customization

IP55, IE4, and IE5 low-pressure motors.

IP55, China National Standard Level 1 high-pressure motors.

High-dust intake filter.

Outdoor option.

Food-grade coolant.

High-temperature option.

The RM series is designed to deliver energy efficiency beyond expectations, enabling users to achieve more output with limited investment. The adoption of ECO-PM Permanent Magnet motors is rooted in core design principles of environmental friendliness, energy saving, and economic viability. This technology reduces environmental pollution from painting processes during manufacturing, improves compressor operating efficiency, lowers operating costs, and facilitates more environmentally friendly machine maintenance while extending motor life, ensuring stable long-term operation of the entire unit.

Area: Southeast Asia

Sales:Bonnie Dai

Whatsapp:+8618301920230

Email:bonnie.dai@ingersollrand-seehigh.com

Area: Middle East and South America Etc.

Sales:Major Yang

Whatsapp:+86-15802188014

Email:major.yang@ingersollrand-seehigh.com

Address:Room 502, building 13, No. 1088, Zhongchun road, Minhang district, Shanghai,China Copyright©2014-2024 Shanghai Seehigh Power Equipment Co. , Ltd.

Area:Europe and Africa

Sales:Sunny Huang

Whatsapp:+86-18106566118

Email:irseehigh001@ingersollrand-seehigh.com